Ukulandelela Usayizi Wethebula Okwenziwe Ngezifiso Inqola Yokudlulisa I-Flatbed

Uhlelo lokuphepha

Ukuphepha kungenye yezinto ezibalulekile ezimotweni zokudlulisa ugesi zikaloliwe. Lolu hlelo aluqinisekisi kuphela ukuphepha kwabaqhubi, kodwa futhi luvimbela izingozi ezibangelwa ukwehluleka kwemishini. Uhlelo lokuphepha lwezimoto zokudlulisa ugesi zikaloliwe ngokuvamile luhlanganisa:

Ukuvikela ukulayisha ngokweqile: Lo msebenzi ungaqapha umthwalo emotweni yokudlulisa. Uma idlula umthwalo olinganiselwe, isistimu izocupha ngokuzenzakalelayo i-alamu futhi ikhawulele ukusebenza okuqhubekayo kwemoto yokudlulisa, ivimbele ngokuphumelelayo izingozi.

I-Emergency braking: Esimeni esiphuthumayo, u-opharetha angamisa ngokushesha imoto yokudlulisa ngokucindezela inkinobho yebhuleki eziphuthumayo ukuze agweme izingozi ezingaba khona zokuphepha.

Idivayisi ezwa ngokuphepha: Amadivayisi afana nezinzwa ze-infrared nezinzwa zomthelela asetshenziselwa ukuqapha indawo ezungeze imoto yokudlulisa. Uma isithiyo sitholakele, imoto yokudlulisa izoma ngokuzenzakalelayo.

Ngochungechunge lwezinyathelo zokuphepha, izimoto zokudlulisa ugesi zikaloliwe ziqinisekisa ukuphepha nokwethembeka kunoma iyiphi indawo, ziqinisekisa inqubekelaphambili eshelelayo yokukhiqiza nokusebenza.

Isistimu yeDrayivu

Isistimu yokushayela ""ingqondo"" yemoto yokudlulisa ugesi kaloliwe, enesibopho sokuguqula amandla kagesi abe amandla emishini ukushayela ukusebenza kwemoto yokudlulisa. Isistimu inezingxenye ezibalulekile ezilandelayo:

Imoto: Injini iyingxenye eyinhloko yesistimu yokushayela futhi inganikeza amandla anele ukuhlangabezana nezidingo zokusebenza ngaphansi kwezimo ezihlukene zokulayisha. Ukukhethwa kwemoto kuthinta ngqo isivinini sokusebenza kanye nomthamo wokuthwala wemoto yokudlulisa.

Idivayisi yokushintsha isivinini: Ngedivayisi yokushintsha isivinini, opharetha angalungisa isivinini sokusebenza semoto yokudlulisa njengoba kudingeka ukuze azivumelanise nemisebenzi ehlukene yokuhamba. Lokhu kuguquguquka kuvumela izimoto zokudlulisa ugesi zikaloliwe ukuthi zisetshenziswe kalula ezindaweni ezahlukahlukene zezimboni.

Ngokulungiselela ukwakheka kwesistimu yokushayela, izimoto zokudlulisa ugesi zikaloliwe zingafinyelela ezokuthutha ezisebenza kahle nezingenamandla amancane, okunciphisa ngempumelelo izindleko zokusebenza zamabhizinisi.

Isistimu yamandla

Uhlelo lwamandla lunesibopho sokuhlinzeka ngamandla aqhubekayo nezinzile ezimotweni zokudlulisa ugesi zikaloliwe. Izingxenye zesistimu zihlanganisa:

Iphakethe lebhethri: Iphakethe lebhethri elisebenza kahle kakhulu linganikeza isikhathi eside sokusebenza kuyilapho lisekela ukushaja okusheshayo ukuze lihlangabezane nezidingo zezindawo zokusebenza eziqine kakhulu.

Uhlelo lokushaja: Isistimu yokushaja ehlakaniphile ingaqapha isimo sebhethri ngesikhathi sangempela futhi ilungise ngokuzenzakalelayo indlela yokushaja ngokuvumelana nezidingo zokushaja ezihlukene ukuze kuqinisekiswe ukuphila nokuphepha kwebhethri.

Ukusebenza kahle kwesistimu yamandla akugcini nje ukuthuthukisa isikhathi sokusebenza semoto yokudlulisa ugesi kaloliwe, kodwa futhi kuthuthukisa kakhulu ukusebenza kahle kwezinto zebhizinisi.

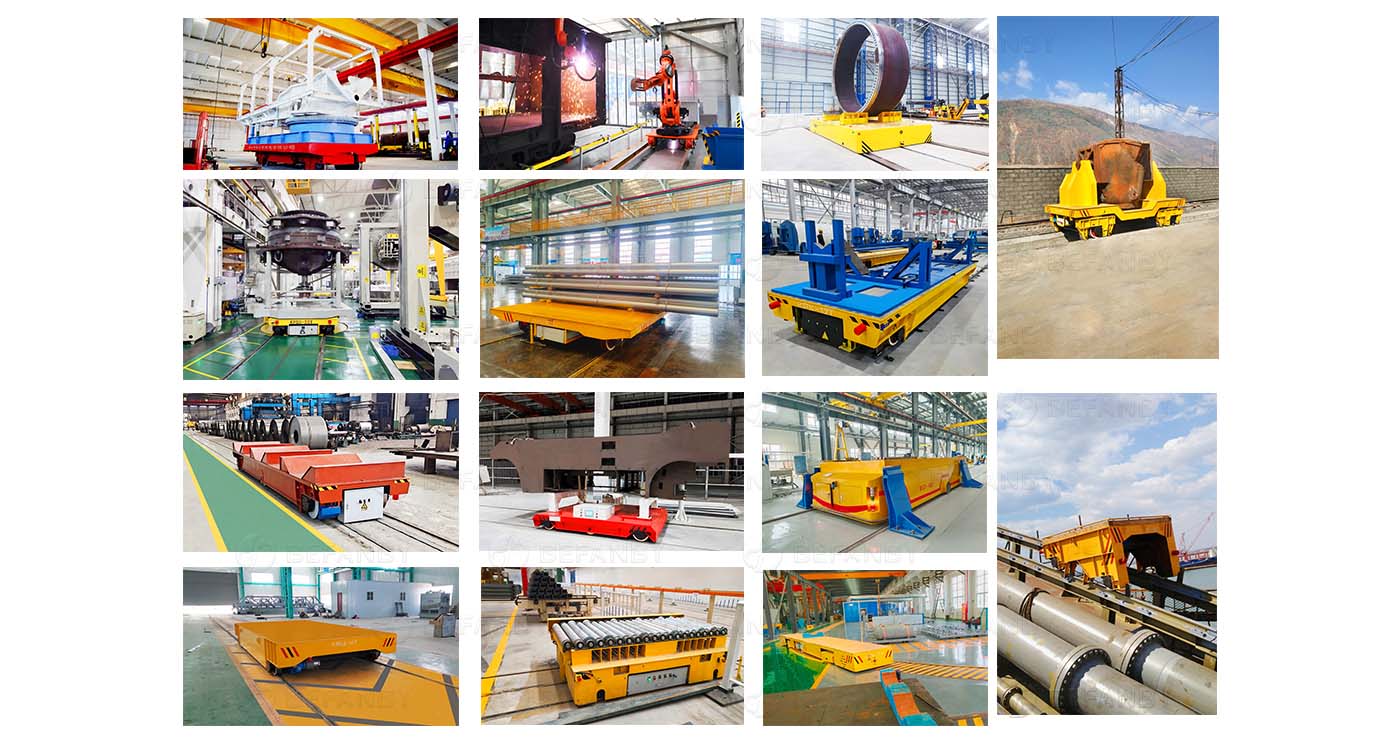

Ngokwezidingo zamabhizinisi ahlukene, imoto yokudlulisa ugesi kaloliwe ingenziwa ngokwezifiso ngezindlela ezahlukahlukene. Lokhu kuvumelana nezimo kuvumela amabhizinisi ukuthi enze izixazululo ze-logistics ezifanelana nezidingo zabo ngokuya ngesimo sangempela esizeni. Izinketho zokwenza ngokwezifiso zihlanganisa:

Ukucaciswa komthwalo: Izinkambu zezimboni ezahlukene zinezidingo ezihlukene zemithwalo yezokuthutha. Imoto yokudlulisa kagesi kaloliwe ingenziwa ngokwezifiso ngezicaciso ezihlukene zomthwalo ngokuya ngezidingo zokukhiqiza zebhizinisi, kusukela kumathani ambalwa kuya kwamashumi amathani, ukuze kuhlangatshezwane nezidingo zezimo ezihlukahlukene zokukhiqiza.

Ubukhulu nesakhiwo: Ngokwesikhala sangempela sefektri, ubude, ububanzi nokuphakama kwemoto yokudlulisa ugesi kaloliwe kungenziwa ngokwezifiso ukuze kuqinisekiswe ukufinyelela okushelelayo ezindaweni zokusebenza ezincane. Ngesikhathi esifanayo, ukuklama kwesakhiwo kungabuye kulungiswe ngezinhloso ezithile, njengokwengeza amabakaki e-pallet noma iziqukathi zokuhlanganisa.

Usekelo lwethimba lochwepheshe ngemuva kokuthengisa

Ukufakwa nokusetshenziswa: Uma imoto yokudlulisa ugesi kaloliwe ilethwa ebhizinisini, ithimba langemva kokuthengisa lizothumela ochwepheshe abaqeqeshiwe esizeni ukuze bafake futhi balungise isisetshenziswa. Bazoqinisekisa ukuthi okokusebenza kusebenza ngendlela efanele ngokwezindinganiso zokuklama futhi babone ngokushesha futhi baxazulule izinkinga ezingaba khona.

Ukugcinwa okuvamile nokuhlolwa: Ukuze kuqinisekiswe ukusebenza kwesikhathi eside nokusebenza kahle kwemoto yokuthutha ugesi kaloliwe, ithimba lesevisi yangemuva kokuthengisa liyohlala linakekela futhi lihlola okokusebenza, lishintshe izingxenye ezigqokiwe kusenesikhathi, futhi liqinisekise ukukhiqizwa okungaphazamiseki. Ngokulungiswa okuvamile, impilo yesevisi yezinto zokusebenza inganwetshwa ngokuphumelelayo futhi nokutshalwa kwezimali kwenkampani kungavikelwa.

Njengethuluzi elibalulekile lezinto zesimanje zokuthutha nezokuthutha, imoto yokudlulisa kagesi kaloliwe ihlangabezana nezidingo zezimboni ezihlukahlukene zezokuthutha nezokuthutha ngokusebenza kahle kwayo okuphezulu, ukuphepha nokuguquguquka. Ngokuhlaziya ukwakheka okunemininingwane, izinketho ezenziwe ngokwezifiso kanye nesevisi ephelele yangemva kokuthengisa, singabona ukuthi imoto yokudlulisa ugesi kaloliwe ayigcini nje ngokuthuthukisa ukusebenza kahle kwebhizinisi, kodwa futhi inikeza isiqinisekiso esiqinile sokukhiqiza okuphephile.