I-Cast Steel Wheels Track Ibhethri 5 Ton Dlulisa Ikalishi

1. Izinzuzo zokwenza ngokwezifiso zamakalishi aqondisiwe

Esinye sezici ezinkulu zamakalishi aqondisiwe izinga eliphezulu lokwenza ngokwezifiso. Izinkampani ezehlukene zinemininingwane yazo ezidingweni zazo zemishini ngesikhathi sokukhiqiza kanye nempahla. Ukuze kuhlangatshezwane nezidingo ezihlukene zamakhasimende, abakhiqizi bezinqola eziqondisiwe bahlinzeka ngezinketho eziningi zokwenza ngokwezifiso. Lezi zinketho zokwenza ngokwezifiso zingabandakanya izici ezilandelayo:

Ukulungiswa kosayizi: Amakhasimende angakwazi ukwenza ngokwezifiso usayizi wezinqola eziqondisiwe ngokuya ngohlobo lwangempela lwempahla kanye nezidingo zokuhamba ukuze kuqinisekiswe ukuphepha nokuzinza kwezinto ngesikhathi sokuthutha.

Umthamo womthwalo: Izimboni ezihlukene zinezidingo ezihlukene zomthamo wokulayisha. Ezindaweni zezimboni ezinomthwalo omkhulu, izinqola eziqondisiwe zingenziwa ngendlela oyifisayo zibe izinguqulo ezinamandla okuthwala umthwalo ukuze zihlangabezane nezidingo zokuphatha izimpahla eziyinqwaba.

Uhlelo lwamandla: Uhlelo lwamandla lwezimoto eziyisicaba zikagesi lungabuye lwenziwe ngokwezifiso ngokwendawo yendawo. Isibonelo, kwezinye izimo ezikhethekile, izinkampani zidinga ukusebenza endaweni encane, futhi abakhiqizi banganikeza izinketho zamandla eziguquguqukayo.

Idizayini yokubukeka: Ngaphezu kokusebenza, ezinye izinkampani futhi zifuna ukwenza ngendlela oyifisayo idizayini yokubukeka ukuze kuthuthukiswe isithombe somkhiqizo. Imibala, ama-logo nezinye izakhi zokuhlobisa zingasetshenziswa ukuhlangabezana nezidingo zomuntu siqu zamakhasimende.

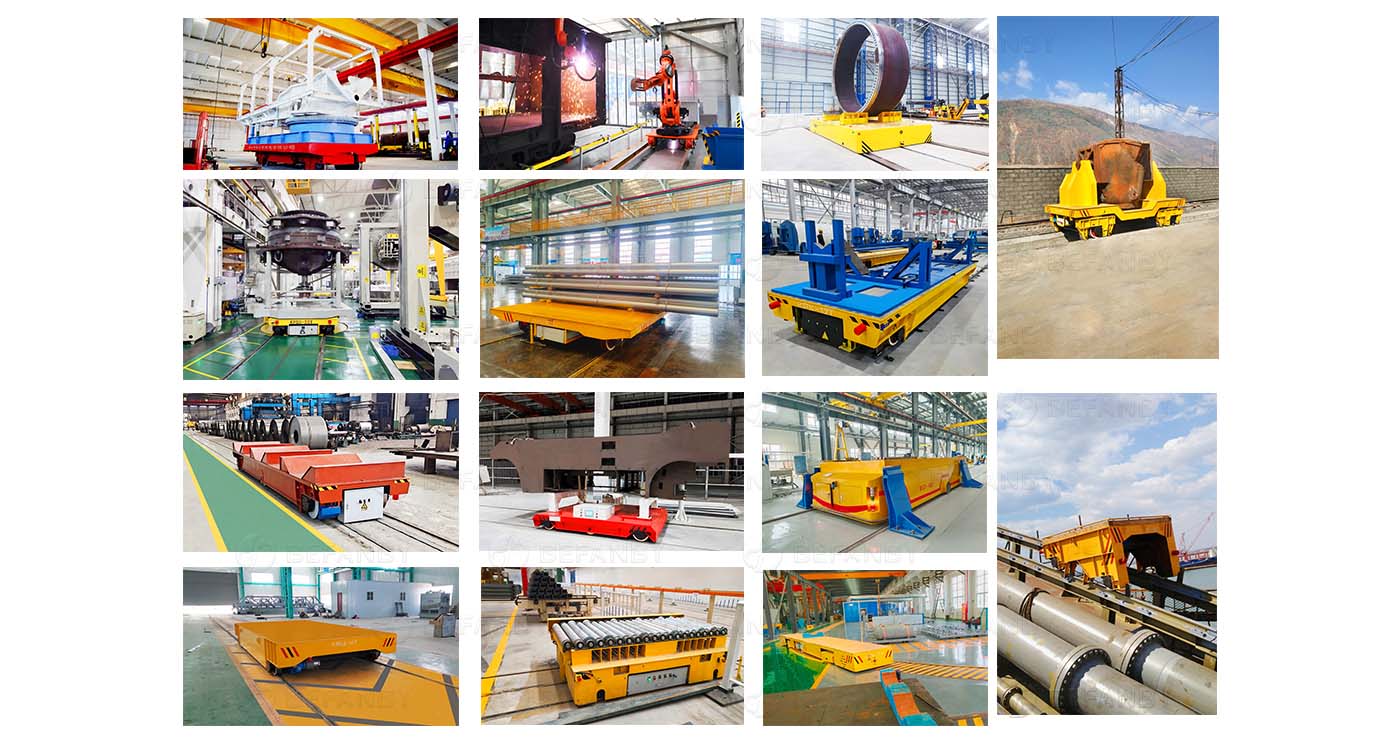

2. Uhlu olubanzi lwezinhlelo zokusebenza

Ukukhiqiza: Ku-workshop yokukhiqiza, izinqola eziqondisiwe zisetshenziselwa ukuthutha imishini esindayo noma izingxenye. Ngamakalishi aqondisiwe, izinkampani zinganciphisa ubungozi bokuphathwa ngesandla futhi zithuthukise ukuphepha kwendawo yokusebenza.

Ukugcinwa kwempahla kanye nempahla: izinqola eziqondisiwe zidlala indima ebalulekile ezinhlelweni zokugcina impahla. Umthamo wayo wokuthutha osheshayo futhi ophumelelayo ungathuthukisa kakhulu ukusebenza kahle kwamashelufu wempahla kanye nokugcinwa kwempahla, futhi unciphise izindleko zabasebenzi.

Izimayini nokwakha: Ezindaweni zezimayini nezakhayo, izinqola eziqondiswayo zivame ukusetshenziselwa ukuthutha izinto eziningi ezifana nesihlabathi, amatshe, inhlabathi kanye nemishini esindayo. Ngenxa yokumelana nokugqwala okuhle kakhulu nokumelana nokuguga, izimoto zikagesi eziyisicaba zingakwazi ukubhekana nezindawo zokusebenza ezinzima.

3. Izinzuzo zensimbi ye-manganese enamandla amakhulu

Ukumelana nokugqokwa okuqinile: Insimbi yeManganese inobulukhuni obuphezulu nokumelana nokugqoka, futhi ingakwazi ukuzivumelanisa nokusetshenziswa kwesikhathi eside komthwalo ophezulu. Uma kuqhathaniswa nezinto ezisetshenziswayo zendabuko, insimbi ye-manganese inokuphila kwesevisi ende, okunciphisa ukugcinwa kwenkampani kanye nezindleko zokushintshwa.

Ukumelana nokugqwala: Kwezinye izimboni, uketshezi noma izinto ezibolayo zingase zidalulwe ngesikhathi sokuthutha. Ukwakheka kwe-alloy yensimbi ye-manganese kunganikeza ukumelana nokugqwala okuhle kakhulu, kuqinisekise ukuthi imoto eyisicaba isengakwazi ukusebenza kahle ezindaweni ezahlukahlukene.

4. Isifinyezo

Njengemishini ethuthukisiwe yezokuthutha zezimboni zesimanje, izinqola eziqondisiwe ziye zaqashelwa kabanzi futhi zasetshenziswa ezimbonini eziningi ngenxa yezimpawu zazo ezenziwe ngokwezifiso, ububanzi bezinhlelo zokusebenza kanye nokusetshenziswa kwensimbi ye-manganese enamandla amakhulu. Njengoba izinkampani ziqhubeka nokwandisa isidingo sazo semishini esebenza kahle futhi eguquguqukayo, izinqola eziqondisiwe ngokungangabazeki zizoqhubeka nokudlala indima ebalulekile.