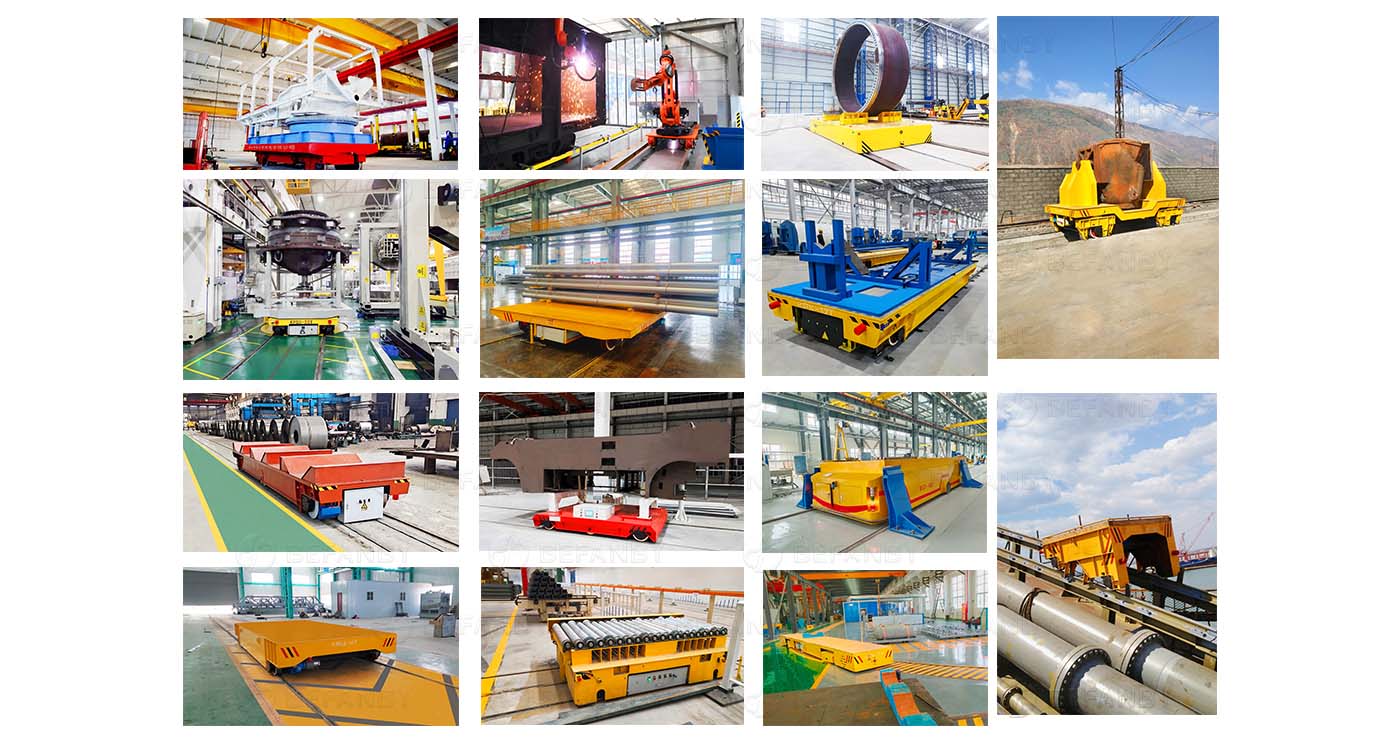

20 Tonne Cast Steel Wheels Railway Transfer Cart

1. Ukusebenza okuhle kakhulu kwensimbi ye-manganese enamandla kakhulu

Insimbi yemanganese enamandla amakhulu isiphenduke into ebaluleke kakhulu ezimotweni zikagesi eziyisicaba ezisebenza ngogesi ezinokumelana nokugqwala okuhle kakhulu. Uma kuqhathaniswa nensimbi evamile, amandla aqinile kanye nokuqina kwensimbi ye-manganese kuye kwathuthukiswa kakhulu, okwenza izimoto zikagesi zikaloliwe zikwazi ukugcina ukuzinza okuphezulu lapho zithwele izinto ezisindayo futhi zigweme ukuguquguquka noma ukwehluleka okubangelwa ukugcwala ngokweqile. Ezimbonini ezidinga njalo ukuthwala izimpahla ezisindayo, ezifana ne-metallurgy, izindiza kanye nobunjiniyela basolwandle, ukusetshenziswa kwezimoto eziyisicaba zikagesi ezisebenza ngogesi kuyisiqinisekiso esiphindwe kabili sokusebenza kahle nokuphepha.

Izimoto eziyisicaba zikagesi zikaloliwe zivame ukuba endaweni yokugqoka okuphezulu ekusetshenzisweni kwansuku zonke, ikakhulukazi enqubweni yokuthwala izinto ezisindayo, ukungqubuzana phakathi kwendawo yokuxhumana kanye nethrekhi kwenza izinto zigqoke kalula. Kodwa-ke, ukwakheka kwamakhemikhali kanye nenqubo yokwelapha eyingqayizivele yensimbi ye-manganese kuyinikeza ukumelana nokuguga futhi inganweba ngempumelelo impilo yayo yesevisi. Ngesikhathi esifanayo, ngokungeza izakhi ezithile ze-alloy, insimbi ye-manganese nayo inokumelana nokugqwala okuhle, okulungele izindawo zokusebenza ezihlukahlukene ezinokhahlo, ukunciphisa imvamisa kanye nezindleko zokunakekelwa.

2. Izinzuzo zesakhiwo zamasondo ensimbi

Ukusetshenziswa kwamasondo ensimbi ensimbi kwenza izimoto zikagesi zikagesi zikwazi ukumelana nomthelela omkhulu nokulayisha ngesikhathi sokusebenza. Isakhiwo sangaphakathi samasondo ensimbi ensimbi siqinile futhi siyafana, futhi sinamandla aphakeme nokuqina kunezinye izinto ezifana nensimbi ekhonjiwe noma ipulasitiki. Lokhu kubaluleke kakhulu, ikakhulukazi uma ugijima ngesivinini esiphezulu noma ukulayisha ngokweqile, amasondo ensimbi anganciphisa ngempumelelo ukungqubuzana phakathi kwesondo nethrekhi futhi agweme ukulimala kwesondo okubangelwa ukushisa ngokweqile.

Ukwakhiwa kwamasondo ensimbi akugcizeleli amandla kuphela, kodwa futhi kugxile ekusebenzeni kahle kokusebenza. Ngesikhathi sokuhamba kwezimoto eziyisicaba zikagesi zikaloliwe, amasondo ensimbi anganciphisa kakhulu umsindo futhi anikeze indawo yokusebenza ethule endaweni yokusebenza.

3. Isistimu yethrekhi eguquguqukayo

Ithrekhi egijimayo yezimoto eziyisicaba zikagesi zesitimela iklanyelwe ukuguquguquka, futhi ubude bethrekhi nesakhiwo kungalungiswa ngokuvumelana nezidingo zangempela. Lo mklamo awugcini nje ngokuthuthukisa ukusetshenziswa kwendawo, kodwa futhi ungenziwa ngezifiso ngokuya ngezidingo zebhizinisi, ukuze ukwazi ukudlala ukusebenza kahle okuhle kakhulu ngezikhathi ezahlukahlukene.

4. Isevisi yokuthengisa emva kokuthengisa

Ithimba lesevisi yangemuva kokuthengisa lizohlinzeka ngezinsizakalo zokufakwa kwemishini yobungcweti kanye nezinsizakalo zokugunyazwa ukuze kuqinisekiswe ukuthi imoto eyisicaba kagesi kaloliwe ingangena ngokushesha esiteji sokusebenzisa ngemva kokuphuma efektri. Ngemuva kokuthunywa ngokucophelela, imishini ingafinyelela esimweni esihle kakhulu sokusebenza, ukunciphisa ingozi yokwehluleka okubangelwa ukufakwa okungalungile.

5. Isifinyezo

Kafushane, ukubaluleka kwezimoto eziyisicaba zikagesi zikaloliwe embonini yesimanje kuyabonakala. Insimbi ye-manganese enamandla amakhulu namasondo ensimbi esetshenziswayo ayinikeza amandla amahle kakhulu okuthwala, ukumelana nokugqoka kanye nokuzinza kokusebenza. Ngasikhathi sinye, insizakalo yochwepheshe ngemuva kokuthengisa iqinisekisa ukusebenza kahle nokuphephile kwemishini. Kungakhathaliseki ukuthi i-metallurgy, imboni yamakhemikhali, i-logistics noma ezinye izimboni, izimoto ezisebenza ngogesi zikaloliwe zizohlinzeka ngokusekelwa okuqinile kokukhiqizwa kahle nokuphathwa kokuphepha kwamabhizinisi ngokusebenza kwawo okuphezulu nokusekelwa okuthembekile kwezobuchwepheshe.